Accelerated method for SSL luminous flux depreciation

Dr. Yuan and his team applied the environmental heat acceleration concept and developed the accelerated test method for SSL products since 2012. The results induce 1 China national standards ( Accelerated luminous flux depreciation test method for LED lighting products (2000 hours), PN:20132656-T-306) and a research paper. This blog is a brief version of the published paper, with the emphasis on the theoretical fundamentals and the verifications.

-

Concept of the Acceleration method:

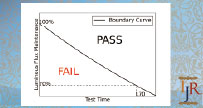

1. Boundary Curve (B-Curve): The lumen maintenance is usually defined as a maintained percentage of the initial light output over time. An LED luminaire or lamp is regarded as passing the qualification test when its luminous flux maintenance stays above a specified curve, which is defined as boundary curve.

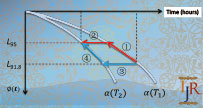

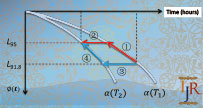

2. The Shape of B-curve: The recommended the exponential decay model for the luminous flux depreciation of the LED packages and modules is the exponential form: `Phi(t)=beta * e ^(-alpha t)`, where `t` and `Phi` are the time and the lumen maintenance at that time, respectively. `beta` and `alpha` are coefficients. Hence, any individual `alpha` will result in a new B-curve. Considering the failure of the lumen depreciation, it is a failure that related to the pile-up of the defects (e.g., in LED chip, packages, etc). If the correlation of the pile-up of the defects with temperature, the Arrhenius Equation is widely acceptable one: `alpha=A*e^(-E_a/(k*T_s))`.

3. Two stage acceleration: Based on these two equations, we can define the lumen + temperature acceleration method. There is a equivalent path: the route of (1)+(2) = (3)+(4).

4. Derive the parameter `alpha` and `E_a`: The derivation of the `alpha` and `E_a` (activation energy) are neglected here, please refer to the paper for the detail. According to the paper, `alpha=1.427e^(-5)` at `T=105 ^oC` has been defined.

5. Therefore, the acceleration method can be summarized as the table. To avoid the fluctuation of luminous flux measurements over time, two additional monitoring points at 900 and 1,200 hours should be kept.

| Testing Stage | Test Temperature (C) | Time (hours) | Lumen maintenance threshold (%) |

|---|---|---|---|

| Seasonging | 55 | 500 | -- |

| Accelerated Test | 55 | 900 | 95 |

| 55 | 1,200 | 95 | |

| 55 | 1,500 | 95 |

-

Validation:

1. Virtual Luminaires: From over 30 LM80 data, good/poor design of heatsink were applied to study the lumen deperication. In summary, among more than 93% of the total 60 virtual luminaires, the qualification results obtained at both `25^o`C and `55 ^o`C are same.

2. Validation study based on the CALiPER’s data: A batch of the accelerated life tests on 15 types of LED A lamps at `45^oC` were conducted

3. Direct measurements: Six LED luminaires including Product 1 (12W spotlight), Product 2 (8W bulb), Product 3 (6W bulb), Product 4 (6W bulb), Product 5 (20W downlight) and Product 6 (16W downlight) were selected as test samples.